The Build – Part 3

The LM-1 uses a unique dual-bellcrank steering system, a setup found mostly in offroad and touring cars. This setup makes the steering feel (and react) a bit differently than a direct-setup and I’m actually loving it.

Build Notes:

When attaching the lower front arms to the chassis, pay attention to which holes you are using in the inserts. If you use the wrong holes, you’ll make the front end REALLY wide.

When attaching the lower front arms to the chassis, pay attention to which holes you are using in the inserts. If you use the wrong holes, you’ll make the front end REALLY wide.

Also pay attention to the pivot balls that install into the outer part of the lower arms. There is a ‘lip’ or flange that must point up.

Also pay attention to the pivot balls that install into the outer part of the lower arms. There is a ‘lip’ or flange that must point up.

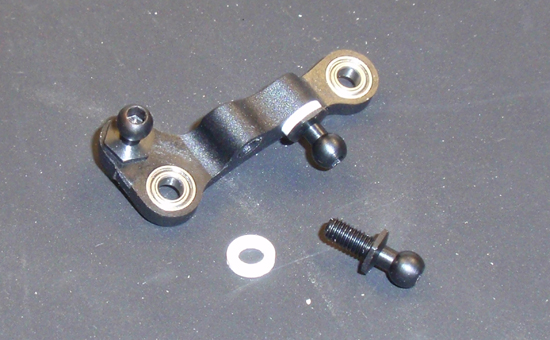

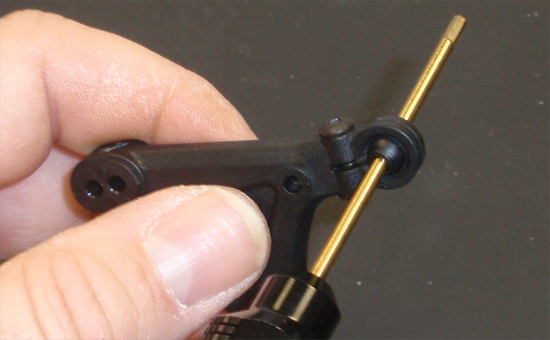

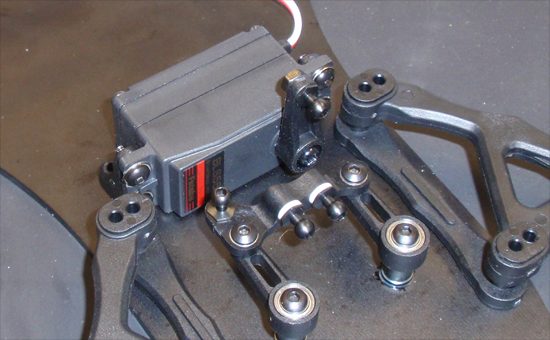

Our first order of business is to assemble the steering rack. Start by attaching 3 ballstuds to the rack, placing a spacer under the two on the front. A small drop of threadlock will keep the upright ballstud securely fastened to the 3mm nut. Press the two bearings into place as shown.

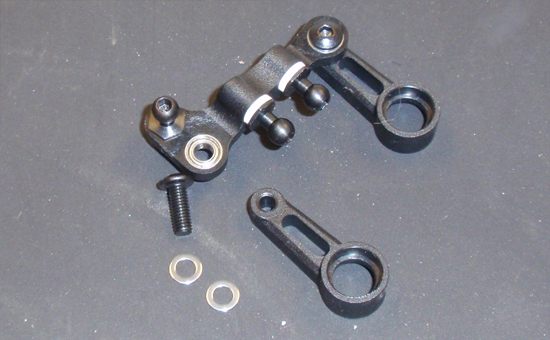

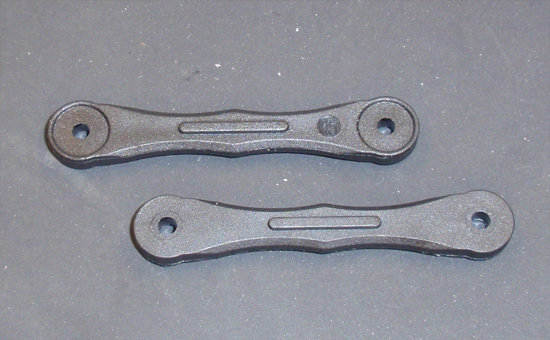

Attach the rack assembly to the bellcrank arms. Make sure the two thin washers go BETWEEN the arm and the rack. There should be free movement in the rack once assembled. Also note the orientation of the bellcrank arms so you don’t install them upside down.

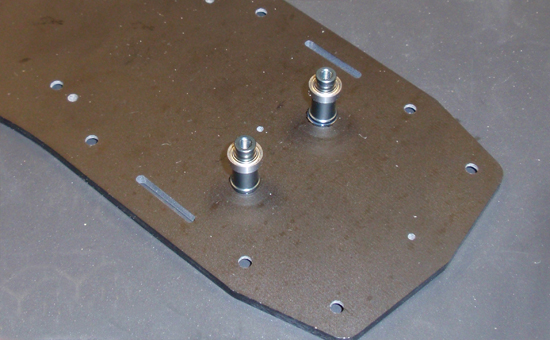

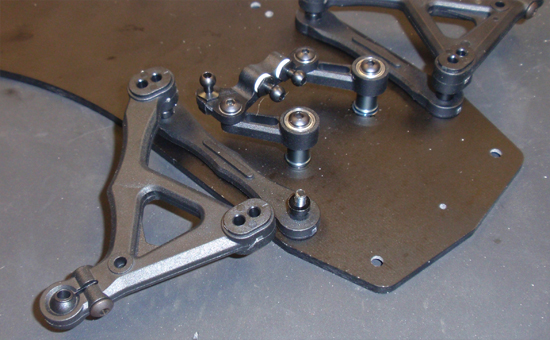

Attach the bellcrank standoffs to the chassis in the holes shown and slide a 5mm bearing over each one. A dab of threadlock on the screws will keep the standoffs secure.

Slide the steering bellcrank assembly onto the standoffs, press another 5mm bearing into place and secure with the 4mm screw.

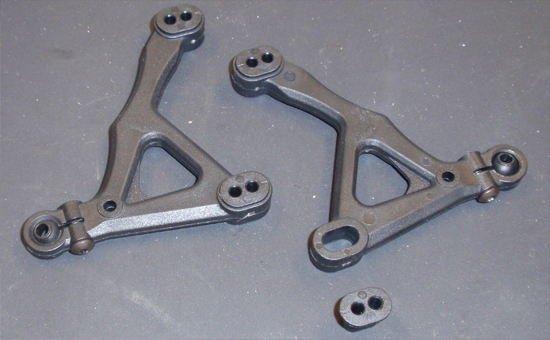

Press the swivel ball into the end of each lower arm and tighten the 10mm screw down. Do not overtighten. Press the arm mount inserts into the lower arms as shown, making sure the mounting line is pointing in (or away from the arm).

Take one of your drivers and insert it into the ball. Roll it around to make sure there is free movement. If not, loosen the screw slightly and try again. You want completely free movement, but not so much that there is slop.

Find the two ride height plates. As you can see, one is facing up, one is facing down (I’m not sure WHAT is up and what is down, but you can see they are different on each side). We will be installing them like the lower one in the picture, with the little printed number facing down.

Slide 15mm screw up through the chassis, through the arm mount, through a pair of 2mm spacers (so 4mm total) and into the arm mount insert. Tighten to a secure snug, but don’t overtighten, and make sure you mount to the hole shown in the manual (or a narrow wheelbase).

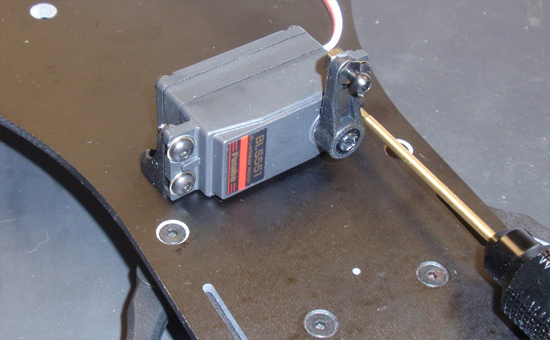

Assemble the mounts and horn to your servo. Do not tighten down the mount screws yet.

Since it’s difficult to reach the mount screws once the servo is installed, we need to make sure the holes are aligned first. Turn the chassis over and mount the servo to the bottom of it as shown. Once mounted, tighten up the 4 mount screws.

Remove the servo, flip the chassis over and re-mount it. Wah-lah, perfect alignment!

Part 4 – Assembling the front suspension.

Part 4 – Assembling the front suspension.

RC Driver The Best In RC Car & Truck News, Reviews & Video

RC Driver The Best In RC Car & Truck News, Reviews & Video