The Build – Part 9

Even though the Axial Yeti XL is a monstrous buggy, the transmission is compact and sits right in the dead center of the chassis. It features an all-metal geartrain and can accomodate almost any 550-size brushless motor.

Let’s get aquainted with the two bearings we will be using during this part of the build. The 5×11 bearing on the left is used inside the gearbox for the top and center shafts. The 6×12 bearing on the right is used for the lower output shaft.

Insert one of the 2x10mm pins into the hole in the top shaft and slide the top shaft gear over it to keep it in place. Slide the long, plastic spacer over the top shaft followed by a 5×11 bearing on each end.

Assemble the idler gear by installing a 5×11 bearing on each end.

Insert one of the 2.5x12mm pins though the output shaft and slide the metal 34T gear onto the shaft and over the pin. Slide the short plastic spacer over the output shaft followed by the two 6×12 bearings on each end.

We’ll now be installing all of the shafts into the transmission case. Start by installing the top shaft, pressing firmly to make sure the bearing seats in the recess.

Next, install the idler gear, pressing firmly to make sure the bearing seats in the recess.

Finally, the output shaft. Before installing, apply a coat of the included grease to the metal gear. Once installed, rotate the output shaft a few times to spread the grease around. Align and install the idler gear support, however do not overtighten the three M2.6 screws.

Attach the other transmission case half to the assembly.

Cover the hole in the case with the rubber plug.

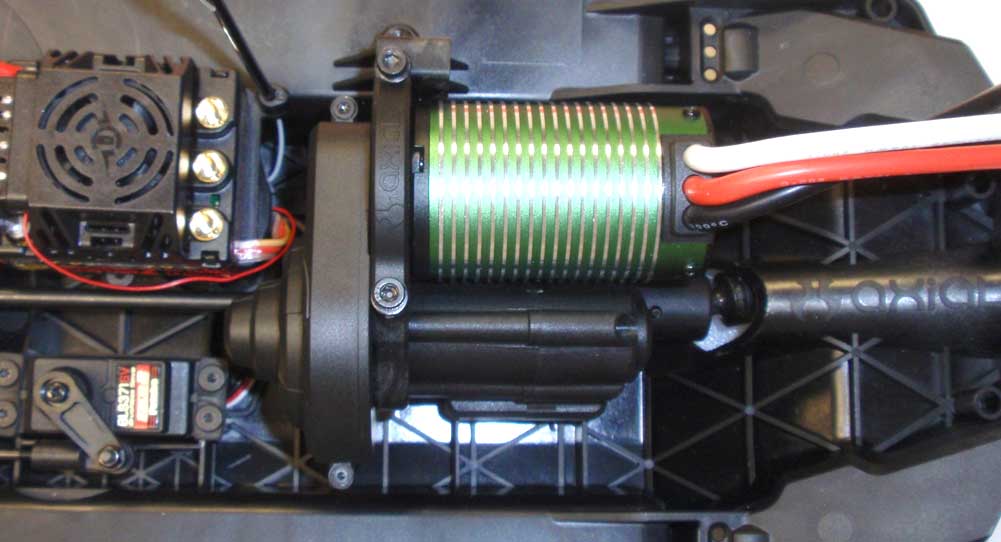

Attach the motor mount to the transmission.

Attach the inner gear cover.

Slide the output cup onto the output shaft and secure with the M4 set screw. Use a dab of threadlocker here to prevent this screw from backing out.

The Yeti features a slipper clutch to help protect the transmission gears. I’ve laid out the parts showing how they will be installed. You probably received a set of plastic slipper pads and a set of metal ones. Scrap the plastic ones; this Yeti is rocking all metal!

Press the plastic spacer into the gear and install a metal slipper pad onto each side of the gear. I used a couple dabs of black grease to keep the pad attached.

Compress the slipper spring a few times to settle it.

Slide the inner slipper plate onto the top shaft followed by a slipper plate washer. Slide the gear assembly into place, another slipper plate washer and finally the outer slipper plate. Once you’re sure all the slipper parts are correctly seated, install the plastic spring centering spacer, the slipper spring, a 4×11 washer and the locknut.

Tighten the locknut down all the way, then back it off until there is about 2mm of shaft sticking out. This is a good starting point for the slipper clutch.

Assemble the motor mounting plate. It can be assembled a few different way but the right way has the holes lined up like the picture.

Attach the motor plate to the motor. Use a dab of threadlocker here to keep the screws in place.

Install the included pinion gear. For now, align the pinion to sit flush with the end of the shaft on your motor. We can fine-tune it in the next step.

Slide the motor mount assembly into the motor plate and secure with the brace. Rotate the motor until your gear mesh is spot on and then tighten down the two M4 screws. You can now adjust the pinion in or out on the shaft to make the best contact with the spur.

Attach the gear cover.

Mate the CVD stub to the center slider and use the M3 screw to keep it all together. A dab of threadlocker is suggested.

Like all the other CVDs, install the barrel into the stub, slide the coupler over the stub, align the holes and slide the pin through. Don’t forget your black grease.

Slide the center slider assembly into the plastic cover. Slide the entire assembly onto the output shaft and secure with the M4 set screw. This cover retains the pin in the CVD. Once again, threadlocker on the set screw to prevent it from backing out.

Slip the center slider through the chassis tunnel, key the front CVD bone into the output shaft in the transmission and it into place. Give it a little wiggle to make sure everything seats correctly and then attach with the four 30mm screws.

Your transmission should now be firmly mounted in the belly of your Yeti XL. Rotate the rear slider drive to make sure everything turns smoothly. Next up is the rear suspension.

RC Driver The Best In RC Car & Truck News, Reviews & Video

RC Driver The Best In RC Car & Truck News, Reviews & Video