Have you ever seen “The Clapper”? You know, that thing they advertise on TV to turn your electrical appliance on by simply clapping your hands. Wouldn’t it be great if you could just clap your hands and your nitro engine would start up? Another clap and it tunes itself? Unfortunately we’re not that lucky, we have to tune the engine to run and or improve performance. But engine tuning isn’t for everyone. Heck, some people are afraid to work on a nitro engine simply because they don’t want to work on its mechanics.

This is where I come in; its time to teach you about needles and utilizing them to tune for performance. But first we’ll need to learn the basics. It’s like the old saying, “You have to learn to walk before you can run.” The same is true when tuning your nitro engine—you have to learn the basics of the carb and tuning terms before you can tune. No matter how advanced you are in engine tuning, it always comes back to the basics. We will look at the high and low speed needles and the idle adjustment screw.

How needle valves work

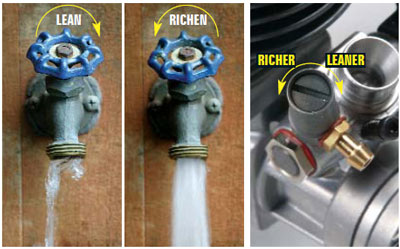

Needle valves are like a garden hose spigot. Open the spigot for more water or close it for less. The same holds true for the fuel, the more you open the needle, the more fuel will flow into the carb.

Find Nitro RC Supplies: HERE

How to adjust the needle

Imagine that the head of the needle valve—the part that looks like a screw head— is a clock face. That screw head gives you twelve hours per one full turn. When tuning, turn the needles in one-hour increments and allow 30 seconds for the adjustments to take full effect. Always tune from rich to lean. If you’re unsure where to begin and you’ve already altered the needle, richen the main needle two full turns from its fully closed position.

Tip: Tune your engine on a day-to-day basis. If you’re racing this Sunday at the local track, and you tune your engine Wednesday during your lunch break at work, you will probably need to retune it Sunday. If you’re bashing around the yard, then tune it in your yard. Always tune the engine with the first tank you are running that day; after you have it set you shouldn’t have to tweak it much more during the day.

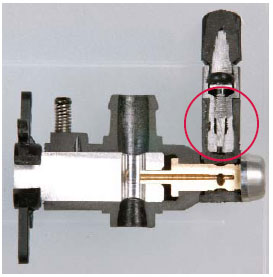

Idle Screw and Low Speed Needle

The idle screw is usually overlooked when talking about engine tuning. The idle screw sets the gap in the carb venturi and regulates the air that enters the carb with the throttle closed. The gap is just as important as the fuel you put in your tank. The gap should be set at about 1mm, or roughly between .9mm and 1.1mm. If the gap is wider, it will trick you into running the low speed needle (LSN) setting too rich to drop the idle. Not good, because the engine will constantly load up with fuel and stall. If the gap is too small, it will cause you to run a lean LSN to get the idle up. Not good, this will cause your engine to run hot and fall out of tune. At 1mm your engine should start and idle.

Start your engine and give it some throttle to clear it out. Now apply the brakes and listen to it idle. If the idle is high and the car wants to move then the LSN is lean. Richen the LSN one hour or until the idle drops to normal. It should idle low enough so the clutch doesn’t engage. If the engine idles low and stalls then the LSN is rich. Lean the LSN one hour and run the engine to allow the setting to take full effect. Apply the brakes and listen to the idle. You want it to idle for three to five seconds before the idle drops and starts to load up. This will give you a slightly rich LSN setting.

After you tune the high speed needle and get the engine up to temperature you can fine-tune the LSN and idle screw for more bottom end and throttle response. Running a slightly rich bottom offers longer engine life and lower engine temperatures. Extending engine life is always good! Just remember the idle screw and LSN work with each other and if one is adjusted the other will require some adjustment to

keep them in sync. Once your idle screw and LSN are set you won’t have to adjust them as often as the high speed needle.

High Speed Needle

The High Speed Needle (HSN) is the main needle on the carb, or by some instruction manuals is just known as the “main needle.” Here we’ll call it the HSN; this needle is used to adjust the amount of fuel at high rpm. Start by warming the engine up for two minutes by doing some laps on the track or just blasting through the yard. After it’s warmed up listen to how the engine sounds on the top end. It should have a slight high pitch sound at high rpm and should have a thin trail of smoke out of the tuned pipe. If it doesn’t seem to clear out on the top end then lean the HSN. Adjust in one-hour increments and always run the engine for 30 seconds to allow for the adjustments to take full effect. Lean the engine until it accelerates smoothly and performs the way you want with a nice stream of smoke from the exhaust. It should smoke at idle and high rpm.

Temperature Check

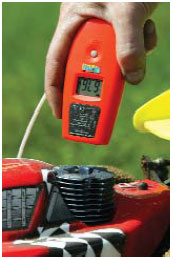

Now after you have tuned your engine; check the temperature. Do this by using a temp gun from Dynamite or ProTek, or by using an telemetry temp sensor like the SBS-01T from Futaba that works with Futaba telemetry radios. A temperature gun or gauge is a great investment for your nitro engine and will last you for many years. Knowing the true temp is always better then guessing and is far better than relying on the water drop test noted below. Try to keep the temperature between 220-270 degrees Fahrenheit. Most engines will operate around 230-250 but you will tend to see higher engine temperatures in hotter weather and cooler ones in cooler weather.

If you don’t have a temp gun or gauge put a drop of water on the head after the engine is warmed up. It should take 3-5 seconds to boil off. If it jumps off as soon as it hits, it means you’re running hot (i.e., lean). Richen the HSN two hours and allow the adjustment to take effect. If the water sits there it means you’re running cool and you could lean the HSN. Only do this if you want more power. Remember keeping a slightly rich setting will always offer longer engine life and lower engine temperatures.

CONCLUSION

Always remember the basics when engine tuning. Turn the needles in small one-hour increments and always have the idle screw set before you make these adjustments. But more importantly, just take your time when tuning. If you take the time to carefully tune your engine, it will last longer and perform better. And this means your nitro experience will be more enjoyable.

ENGINE TUNING TERMS

CARBURETOR (CARB)— The engine component that regulates the flow of the air-fuel mixture into the engine.

CLEAR OUT— You “clear out” the engine when you apply a short burst of throttle to stop the engine from loading up.

HIGH SPEED NEEDLE (HSN)— Also know as the Main Needle, this adjusts the flow of fuel into the carburetor.

IDLE SCREW— Adjusts the gap between the carb housing and slide or barrel to regulate how much air can enter at idle.

LEAN— You “lean” the engine when you turn the needle clockwise to restrict fuel flow.

LOAD UP— This occurs when your engine ”loads up” with fuel inside the crankcase that, in turn, causes your engine to stall.

LOW SPEED NEEDLE (LSN)— Needle, which can be on either side of the carb, that adjusts low-rpm fuel flow.

RICHEN— means to turn the needle counter-clockwise that allows more fuel to enter the engine

VENTURI— The passage through which air flows into the carb.

*Notice: Some of our articles, videos and descriptions may contain affiliate links or coupon codes, which means that if you click on or use one of the product links/ codes, we may receive a small commission. This helps support the website and social media channels and allows us to continue to produce content. Thank you for the support!

RC Driver The Best In RC Car & Truck News, Reviews & Video

RC Driver The Best In RC Car & Truck News, Reviews & Video