8 point check to maintain performance

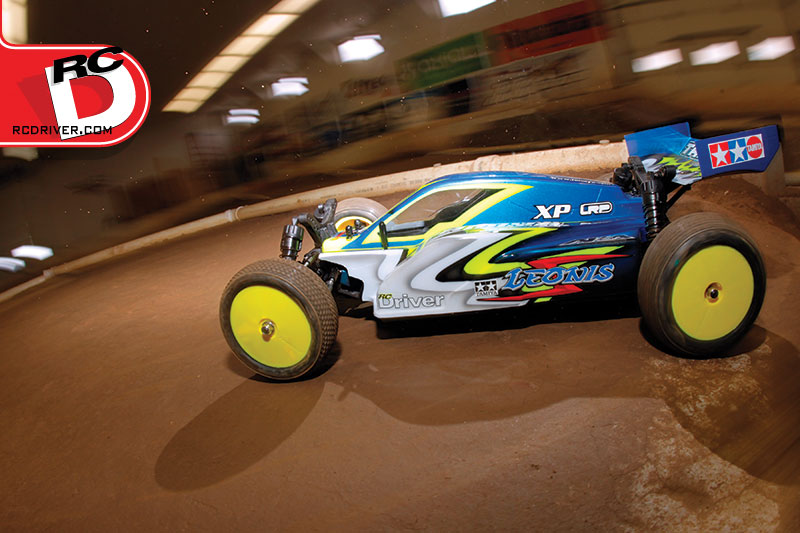

So, you’ve bought yourself a shiny new off-road buggy or truck. You spent hundreds of dollars getting the best equipment and you’ve taken several hours out of your busy schedule to build it just right. You head to the track for your first race, you have a great time and who knows, you might have even finished your race day on the podium. Now what? Well, post-race car care is one important part of competitive racing that you should never overlook. Here is an eight point check which can be performed immediately after a race to keep your vehicle in top form.

1 – Tires

After I clean the tires with Simple Green, I check to make sure they are still well glued to the wheels and if necessary, I re-glue them. I also look for tread wear. Some of the new soft compound tires wear very fast. If the tread is worn out, then it’s time to replace the tires.

2 – Wheels

Inspecting the wheels is one of those spots that are easily overlooked. First, make sure there are no cracks or breaks in the wheel. Then check the center of the wheel to ensure the space that is keyed onto either a hex hub or pin is not worn or damaged. High power vehicles tend to wear this part of the wheel out and it can get damaged if the wheel is tightened when the hex hub or pin is not seated properly in the wheel.

3 – Shocks

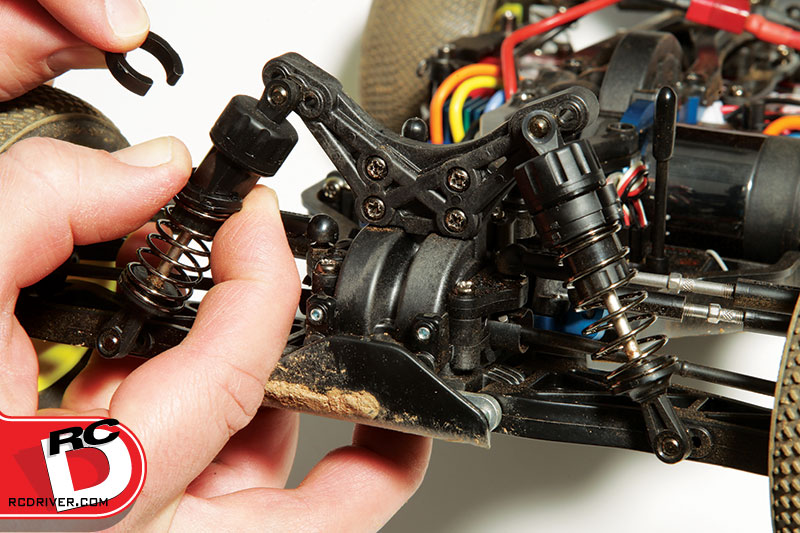

Start by checking to make sure you still have the same amount of preload spacers on the shock bodies that you started with. If your vehicle is equipped with threaded shock bodies, verify they are still in the same spot.

Next, check to see if the shock shafts are straight. A hard hit can often bend a shock shaft slightly and cause the suspension to bind. If a shaft is bent, don’t try to straighten it and buy a new one.

Last, verify that no oil has leaked out. If a bit of dirt has built up around the bottom of the shock body where the shaft goes in and out, this is a good indication that oil is slowly leaking. Another way to check this is to turn the shock upside down and gently compress the shock. You will feel a dead spot right away if oil has leaked out. There are several reasons a shock might leak. First, the shaft may have deep gouges or scratches. If this is the case, replace the shaft. Another cause of leakage may be that the shock seals are worn. Simply replace them if this is the case. In addition, some of the top racers in the world will change their shock oil after every race day. When running on a dusty track, where oil can become dirty faster, they will change it after one or two runs!

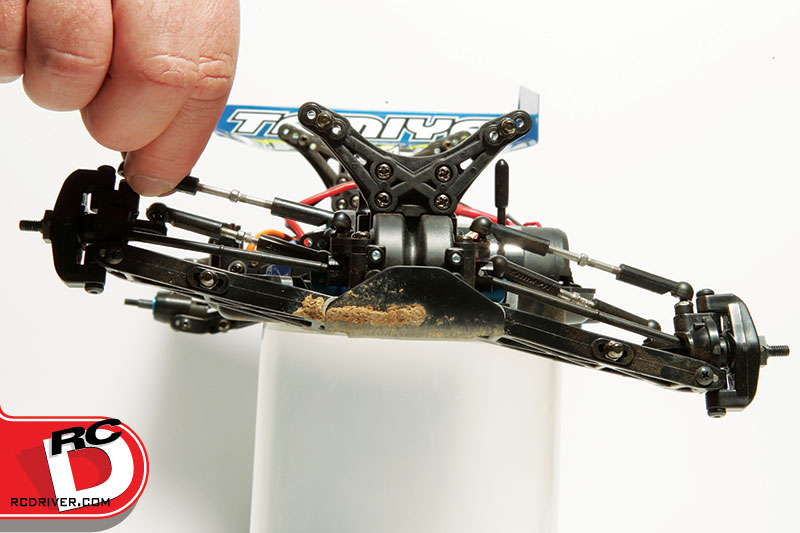

4 – Suspension arms

With the shocks removed from the vehicle, test to see that each suspension arm is moving freely. Simply lift each arm and check that it drops with little or no friction. If an arm is stuck and either does not drop or drops slowly, remove the hinge pins. Sometimes, simply removing them will free any dirt and debris that is causing the suspension to bind. Other times you may find that a hinge pin is bent and will need to be replaced.

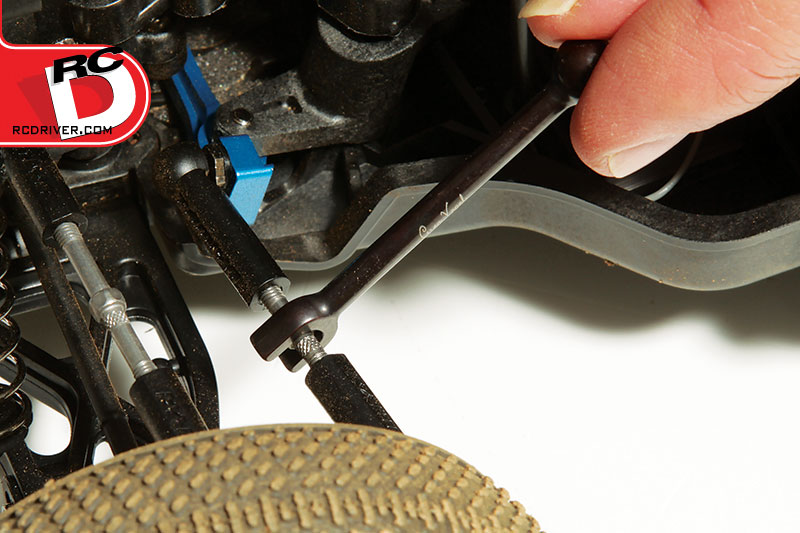

5 ¬– Turnbuckles

Turnbuckles can sometimes be ignored, although they shouldn’t be. If one of these little suckers gets bent or is just simply out of adjustment, it can throw camber or toe out of whack and leave you with a poor handling vehicle. If a turnbuckle is bent, replace it and it is a good idea to also replace the ball cups too. If the toe or camber is simply out of whack, just grab a turnbuckle wrench and a camber gauge to readjust your settings.

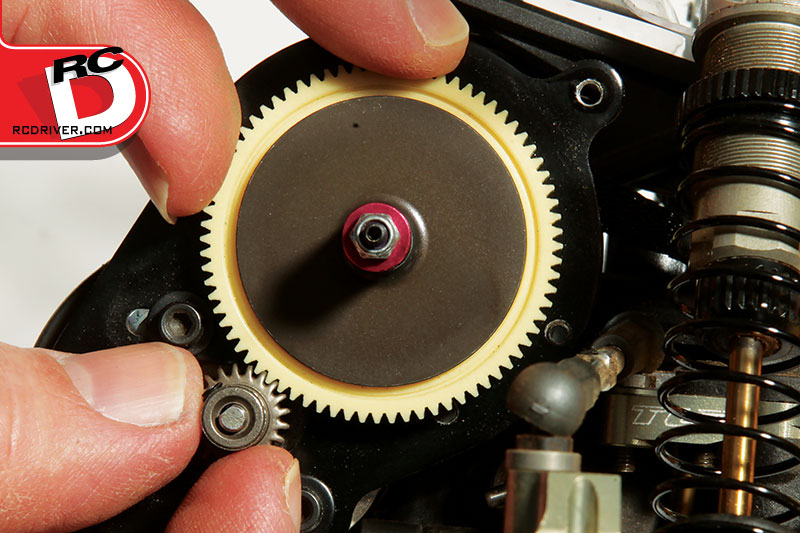

6 – Gears

It is important to check the gears. I make sure that no tiny rocks or debris have made their way past the gear cover to cause the pinion and spur to mesh improperly. Sometimes, just using a simple X-Acto blade can remove any foreign objects impeding the gear mesh. If a gear is worn too badly, it is a good idea to replace the gear. While examining the gears, check to see if the pinion gear is still fastened tightly to the motor shaft and that the motor has not loosened up in the motor mount. This could cause poor gear mesh and will lead to a stripped gear.

7 – Wiring

The wiring of an electric off-road race car is vital. Always check the steering servo and speed control plug are firmly pressed into the receiver. Next verify that the three main motor wires and the battery wires have not frayed. If you are using a connector, check these for wear, too. If you are using a sensored motor and speed control, you should check the sensor wire harness. Make sure each individual wire is still in good repair and make sure both ends are properly plugged in, too.

8 – Hardware

Always go through your entire vehicle and check for loose screws and nuts. You should do this not just after each race day, but after each heat. It is always advisable to use a small amount of thread lock on all metal-to-metal connections when tightening things up. But remember not to over-tighten! Doing this can cause unwanted binding which may cause connections to strip.

Words By: Dean Berry

Photos By: Walter Sidas

RC Driver The Best In RC Car & Truck News, Reviews & Video

RC Driver The Best In RC Car & Truck News, Reviews & Video