The Build – Part 6

In Part 6 of our build, we’ll work on installing the electronics. Even though this is a vintage build, we won’t be installing vintage electronics. The RC10 Classic will be getting a full range race-spec XP, LRP and Reedy equipment to get ‘er up and going with the least amount of headaches.

Build Notes:

Have a soldering iron handy for this step. You’ll need to attach the ESC wires to the motor and solder plugs to the battery wires.

Have a soldering iron handy for this step. You’ll need to attach the ESC wires to the motor and solder plugs to the battery wires.

The steering setup is like the original but can be reworked to use a turnbuckle if you wish.

The steering setup is like the original but can be reworked to use a turnbuckle if you wish.

Yes, this first step has nothing to do with the electronics, but it also has nothing to do with the shocks (which we built and attached in the last step). Anyway, take a sec and install the two nose tubes as shown. Make sure you install the shorter screws in the sides of the chassis and the longer ones through the front. A dab of threadlock here will help keep the screws from backing out.

Next, install the antenna mount…

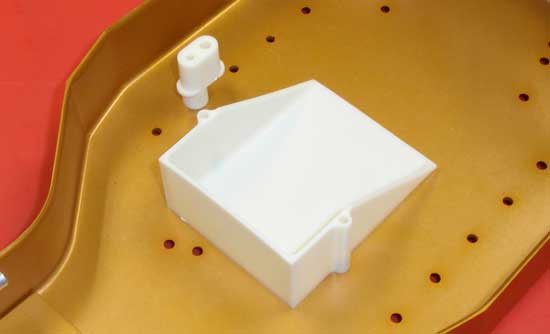

…followed by the battery cup…

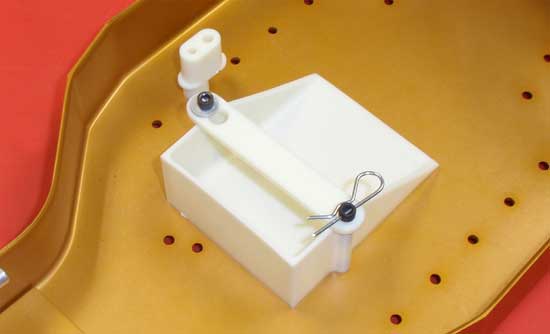

…following that by the battery strap. Note the orientation of the strap, and don’t forget to install the aluminum washer.

The steering linkage is next. It’s easier to assemble than it appears…just build it like the picture. I wouldn’t worry about the threadlock just yet as we’ll need to loosen those set screws again shortly.

Once built, feed one end through the servo horn as shown. You may need to open up the hole in the horn a bit to get the linkage through.

Attach the horn to the servo using the servo-supplied screw. Your assembly should look like this. For this build we are using one of Team Associated’s XP servos; the DS1313.

Attach the mounts to each side of the servo but do not tighten all the way yet.

Because mounting the servo in the car makes it difficult to tighten up the mount screws (or line up the mount holes through the chassis), we always mount the servo to the bottom of the chassis first. This allows us to line up the servo mount holes with the chassis and then tighten the screws that hold the servo to the mounts.

Remove the servo from the bottom of the chassis and install correctly. You’ll want to slide the other end of the steering linkage into the servo saver prior to mounting the servo to the chassis. Also, you might notice that my linkage is bent. This helps it clear the servo when it’s at full lock. You may have to do something similar if your linkage hits the servo.

Once mounted, turn the servo horn until it is 90 degrees straight up. If your front tires are pointing straight ahead, you’re good to go. If not, loosen the set screws on the linkage and ‘slide them apart’ to adjust. Once in position, you can put a tiny dab of threadlocker onto the setscrew and tighten them down.

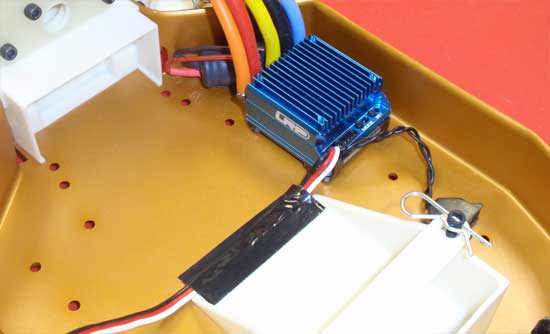

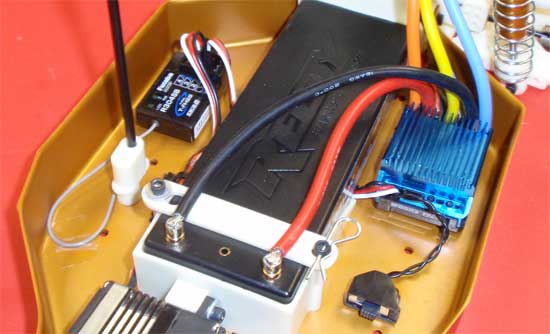

Install the ESC on the right side of the chassis as shown. Since I’m running the ESC lead under the battery, I added a small piece of black tape to hold it in place. For this build we are using LRP’s awesome Flow WorksTeam Brushless ESC.

The Futaba 4PLS reciever gets mounted on the left side. Feed the antenna through the mount and tube. Plug the ESC and servo leads into the receiver.

Slide the Reedy Sonic 540 17.5T Spec Brushless Motor into place and attach with the 3x6mm screws.

Attach the pinion, set the gear mesh and tighten down the 3x6mm screws.

Attach the gear cover and dust plug.

Wire up the ESC wires to the motor and attach the sensor wire. If you feed them through the fiberglass shock tower, you might want to sand the edges slightly to avoid cutting the wires.

Install the battery and plug it in! This is a good time to give it a test to make sure everything is working.

Stay tuned for part 7 – Assembling the wheels and tires.

Stay tuned for part 7 – Assembling the wheels and tires.

RC Driver The Best In RC Car & Truck News, Reviews & Video

RC Driver The Best In RC Car & Truck News, Reviews & Video