The Build – Part 5

In Part 5, I’ll be assembling the transmission of the TLR 22SCT. Although we have the option to build it as a MM (Mid Motor), I’ve opted to build it as a RM (Rear Motor) layout. That’s the most popular at my local track.

Build Notes:

I’ll be working with greases to build the differential. Get some paper towels to help keep things clean.

I’ll be working with greases to build the differential. Get some paper towels to help keep things clean.

The slipper pads fit into grooves on the spur gear. The fit is not tight, nor do they ‘snap’ into position, so be careful during this part of the assembly that they don’t fall out of the grooves

The slipper pads fit into grooves on the spur gear. The fit is not tight, nor do they ‘snap’ into position, so be careful during this part of the assembly that they don’t fall out of the grooves

The first step is to build the differential. Put a dab of grease on the outdrives and then seat the rings in place. The grease helps keep the rings attached to the outdrives.

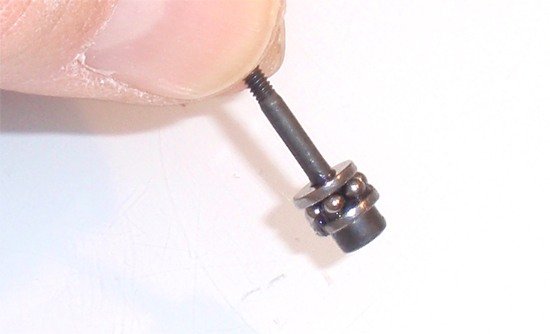

Slide a thrust washer over the thrust screw and apply a liberal amount of black grease…

…and ‘roll’ it over the small, 2mm balls to ‘pick them up’.

Make sure the balls seat flat against the thrust washer. Now slide the 2nd thrust washer over the assembly.

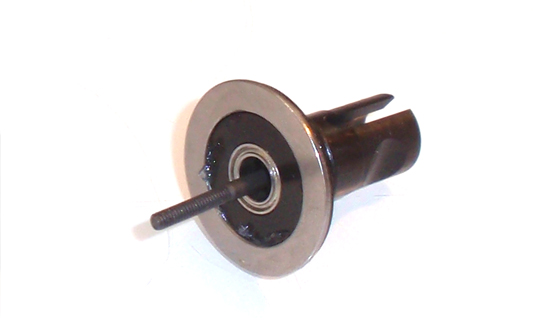

Insert a 5×8 bearing into the ‘female’ diff housing, then slide the thrust washer assembly into place as shown.

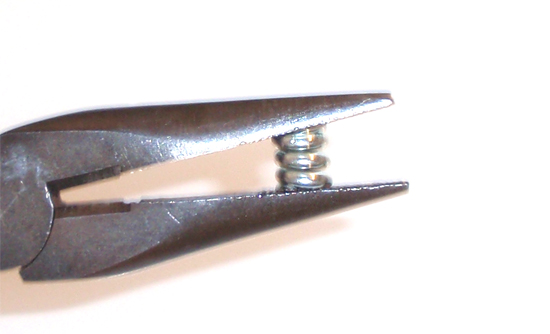

It’s always a good idea to pre-compress any springs. Do this with the diff spring prior to installation.

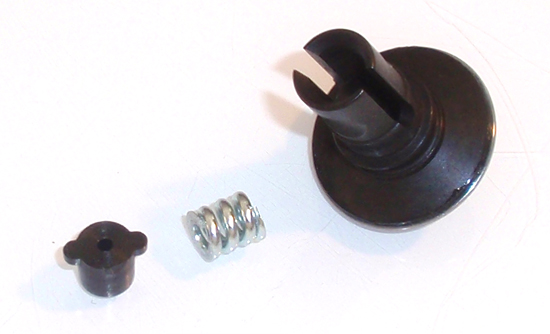

Drop the spring into the ‘male’ diff half followed by the diff nut housing.

Slide the 5×8 bearing onto the ‘male’ diff housing followed by the diff gear.

Fill the diff ball holes with clear grease. Drop the 14 diff balls onto the diff gear as shown…

…and move into position, pressing them down into the holes.

Slide the two diff assemblies together and tighten the diff thrust screw. Tighten down until it bottoms out, working the diff every turn or two. Once bottomed out, back it off approximately 1/8 of a turn. It should feel nice and smooth.

Slide the diff thrust nut protecting piece into place.

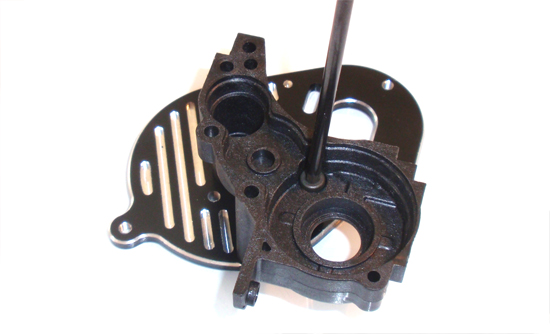

Attach the transmission case half to the motor plate with the single screw as shown. Add a small dab of threadlock here.

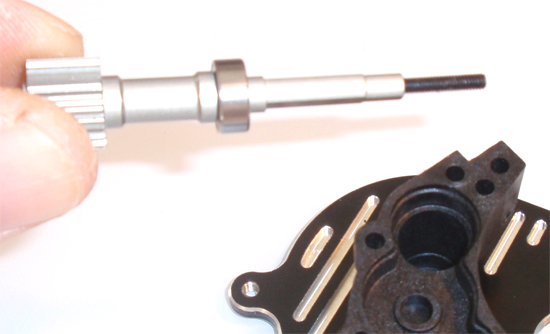

Slide a 5×10 bearing onto the top shaft and insert that assembly into the transmission case.

]

Assembly the idler gear with two 5×10 bearings as shown.

]

Assembly the idler gear with two 5×10 bearings as shown.

Slide a pair of 10×15 bearings on to each side of the differential.

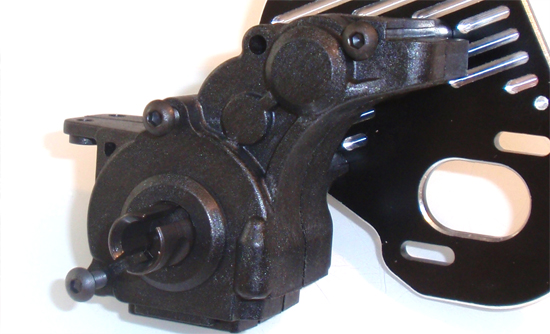

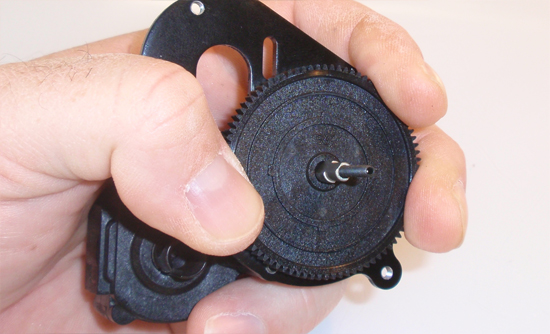

Slide the idler gear assembly into place followed by the differential. Make sure the diff thrust screw is facing AWAY from the motor plate.

Slide the opposite transmission case half into place and secure with the three screws (1 3×16, 1 3×35, 1 3×40). A small drop of threadlock on the two longer screws will help keep them from backing out.

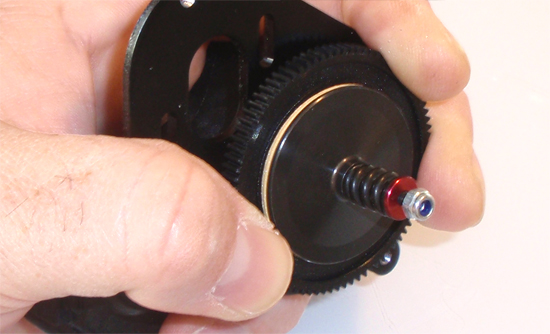

Pre-compress the slipper spring.

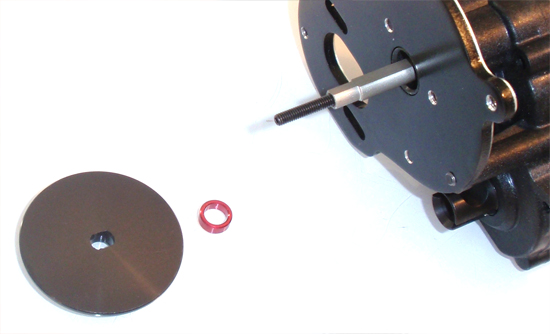

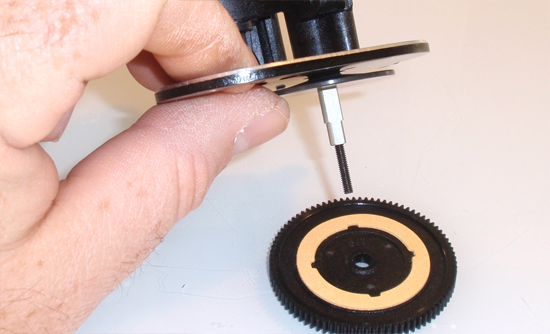

Slide the red washer onto the top shaft followed by a slipper plate. Both plates are the same and feature a flat spot to key to the top shaft.

Press a slipper pad into the grooves of the spur gear. Slide the gear assembly onto the top shaft. I found it easiest to face the top shaft down (as shown) to make sure the pad stays in the grooves on the gear during assembly.

While holding the spur gear assembly tight (making sure the pad doesn’t fall out of the grooves in the gear)…

…slide the second slipper pad, second slipper plate, slipper spring, slipper washer and slipper nut into place.

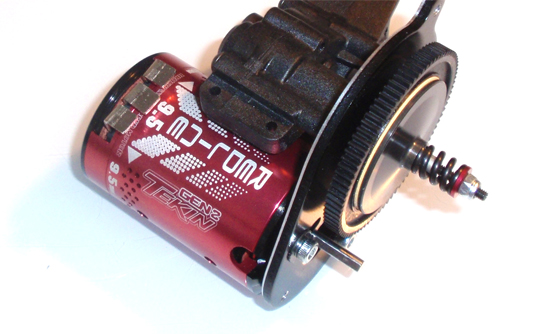

Tighten down, making sure the slipper pads stay in the grooves of the gear. I tighten down quite a bit; final adjustment will need to be done at the track. You can also attach your motor and pinion gear at this time.

Attach the gear cover, followed by the slipper adjustment plug.

Part 6 – Assembling the rear bumper.

Part 6 – Assembling the rear bumper.

RC Driver The Best In RC Car & Truck News, Reviews & Video

RC Driver The Best In RC Car & Truck News, Reviews & Video